Are you considering entering the wood pellet production industry? It’s a market full of potential, especially with the growing demand for renewable energy worldwide. As the sales manager at Tirox, I’d like to share some practical steps to help you smoothly start your wood pellet production business.

Market Research and Demand Analysis

Before diving in, understand who your target customers are. Are they home heating users, industrial fuel buyers, or international trade partners? Conducting market research to gauge the demand and regional distribution of wood pellets and checking out competitors in your market is crucial. Understanding the market’s needs and competition landscape will give you an advantage.

Finding the Right Production Site

A pellet production facility requires ample space for storing raw materials, equipment, and finished products. Ideally, the site should be close to raw material sources or a convenient location for transportation to save on logistics costs and reduce delivery time.

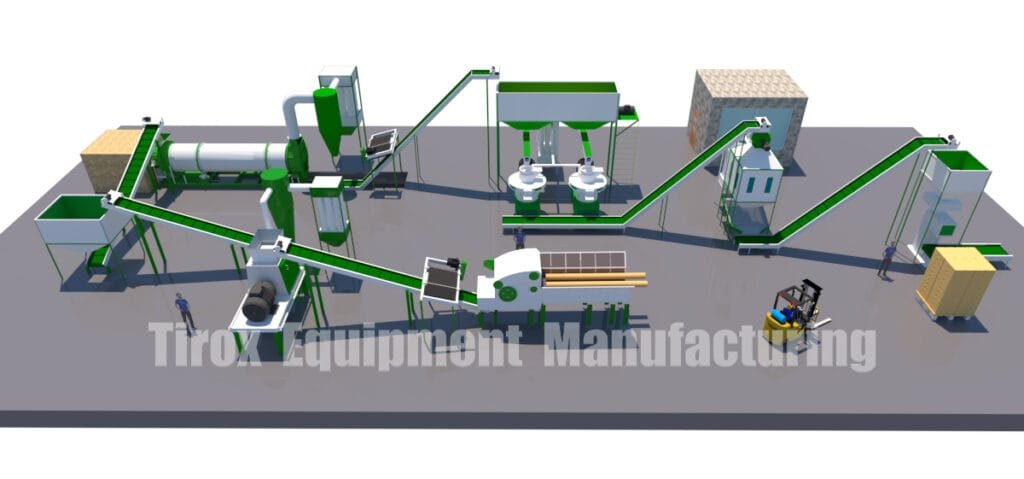

Selecting the Right Equipment

Efficient production equipment is the heart of wood pellet production. The typical setup includes chippers, crushers, pellet mills, dryers, and coolers. When selecting equipment, consider efficiency, energy consumption, and quality to ensure it’s stable and easy to maintain. Tirox offers ISO and CE-certified equipment. Feel free to reach out to me—we even offer customization services to help you find the best equipment mix.

Ensuring a Stable Raw Material Supply

Wood pellets can be made from wood chips, branches, straw, and other biomass materials. Establishing a stable raw material supply chain is essential to ensure adequate supply and fair prices. Compare suppliers and, if possible, set up backup sources to prepare for raw material price fluctuations.

Optimizing Production Processes

The wood pellet production process includes crushing raw materials, drying, pelletizing, cooling, and packaging. Ensure your team is familiar with each step, especially with equipment operation and maintenance requirements, to minimize downtime. Tirox equipment features intelligent control systems to enhance efficiency and reduce maintenance costs.

Compliant Production and Certifications

Different markets have various environmental and safety requirements for pellet production, such as dust control and noise standards. Ensuring that your equipment and production process meet ISO, CE, and other international standards will help add credibility to your product. Tirox equipment is certified to high standards, which can help build customer trust in your products.

Developing Marketing and Sales Strategies

Once your market analysis, equipment purchases, and raw material storage are complete, it’s time to promote your product. You can build a website, register on B2B platforms, or attend trade shows to increase brand visibility. Giving your product a clear positioning, like “high-quality, eco-friendly,” will attract more potential clients. Tailoring different sales strategies for home and industrial users will also expand your market reach.

Effective Financial Planning and Cost Control

Starting a wood pellet business requires a certain capital investment, including for site setup, equipment, and raw material purchase. Managing costs efficiently can increase your profit margins. Choose energy-efficient equipment, manage inventory well, and control cash flow to ensure smooth operations. The cost-effective and low-maintenance Tirox equipment can help you control production costs effectively.

Ensuring a Stable Supply Chain

A reliable supply chain is essential for wood pellet production, from raw material procurement to product delivery. Optimize logistics and arrange transportation according to demand to lower costs and improve delivery punctuality.

Staying Up-to-Date with Industry Trends and Maintaining Flexibility

The wood pellet industry is constantly evolving with new technologies and market demands. Staying informed about market changes through industry news, forums, and trade shows can help you adjust your strategy in time to maintain a competitive edge. Joining industry associations and networking with peers can also open new opportunities for your business.

Conclusion

Starting a wood pellet production business requires solid preparation, but the rewards are promising if you take it step by step. I hope this practical guide is helpful for you! If you’re interested in equipment or want more information about the production process, feel free to contact me. I’m Christina, the sales manager at Tirox, and I’m here to help you find the best equipment mix for your pellet production business.