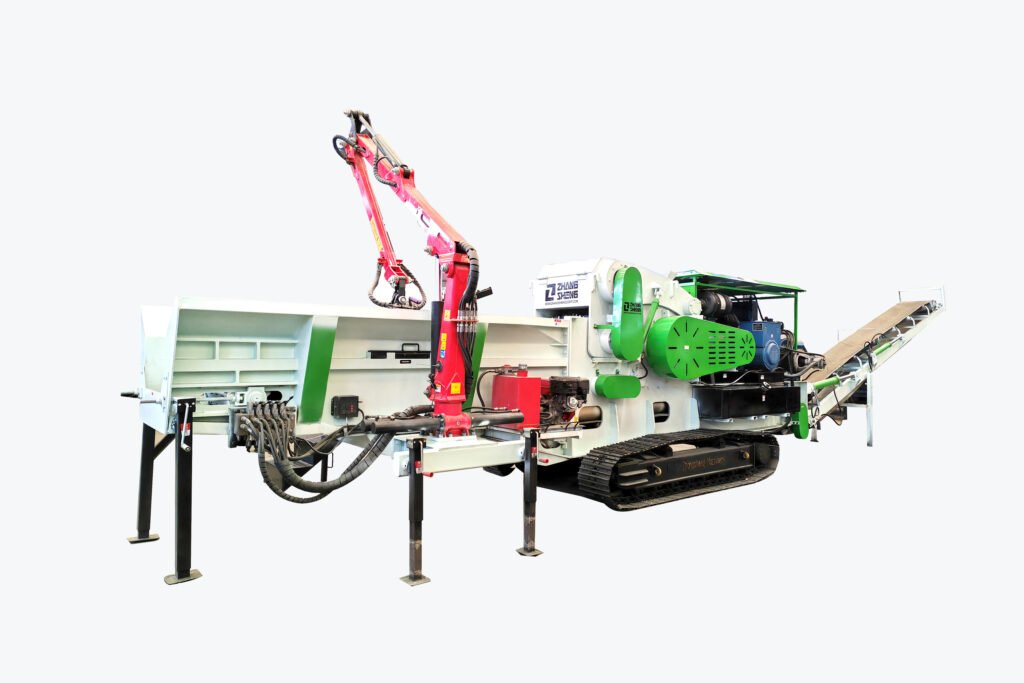

Tirox - Leading Wood Processing to New Heights, Custom Solutions for Any Wood Challenge.

From Proven Past to Global Future: Introducing Tirox (formerly Zhangsheng)

Product Categories

Your Challenges, Our Tailored Solutions

At Tirox, we believe a wood chipper isn’t just a standard industrial machine; It also faces diverse environments, different usage habits and specific processing requirements.This is why we’ve established our Solution Center, compiling years of client challenges and our proven answers.

Your raw materials, output requirements, and application will determine the perfect match. Let us know these three core needs, and we will ensure you get a wood chipper configured for maximum efficiency and return on investment.

Hot, cold, dusty? Environment impacts performance. Overheating in tropics or cold starts in winter need tailored solutions. We customize functions for your specific operating conditions.

Parts wear? Performance decline? We archive every product sold, ensuring lifetime access to international standard parts. We continuously upgrade components (e.g., A8B blades, auto-greasing) to extend machine life.

Deepen Your Industry Knowledge with Our Blogs

The Powerhouse Behind Tirox: Our Manufacturing Might

Our robust manufacturing facility is the cornerstone of Tirox’s commitment to durability and performance. We focus on creating equipment that withstands the toughest operational demands. Through advanced production techniques and stringent quality checks, we ensure every Tirox machine delivered worldwide is a reliable asset for your business operations, offering long-term stability and efficiency.

Witness the Trust: Our Global Network of Partners and Users

Our commitment to excellence has earned the trust of clients worldwide. From our valued agents to satisfied end-users, see who visits our factory and partners with Tirox for their wood processing needs.

Inspect The Real Machine

You can see the robust structure of our equipment for yourself, and our frontline technical engineers will be on-site to answer all of your questions on the spot.

Ensuring Unrivaled Quality Throughout Your Entire Product Journey

Our 3-step QC process, from sourcing to delivery, ensures your equipment arrives rock-solid

We eliminate design risks for you before production even begins.

Your machine arrives tested and ready to work immediately.

Ready Stock & Delivery Capacity

Seeking Worldwide Partners

If you’re clearly intrigued by the Tirox difference. Are you ready to expand your business and unlock new opportunities with a leading global manufacturer? Join us in delivering cutting-edge solutions to the world.

Your Questions Answered

Have questions about doing business with Tirox? We answer a range of common questions from businesses like yours.

We have fully considered the operational needs of the equipment in hot regions. For diesel engines, we ensure that their water-cooled radiators are well-designed and remind you to regularly clean the wood chip dust on the surface to maintain optimal heat dissipation. For hydraulic systems, high temperatures may cause the hydraulic oil to thin and affect power. Our solutions include:

- Equipping a hydraulic oil cooler to actively cool the hydraulic oil.

- Recommending the use of high-viscosity (such as 68-grade) high-temperature resistant hydraulic oil.

- Designing a larger hydraulic oil tank as needed to enhance natural heat dissipation capacity.