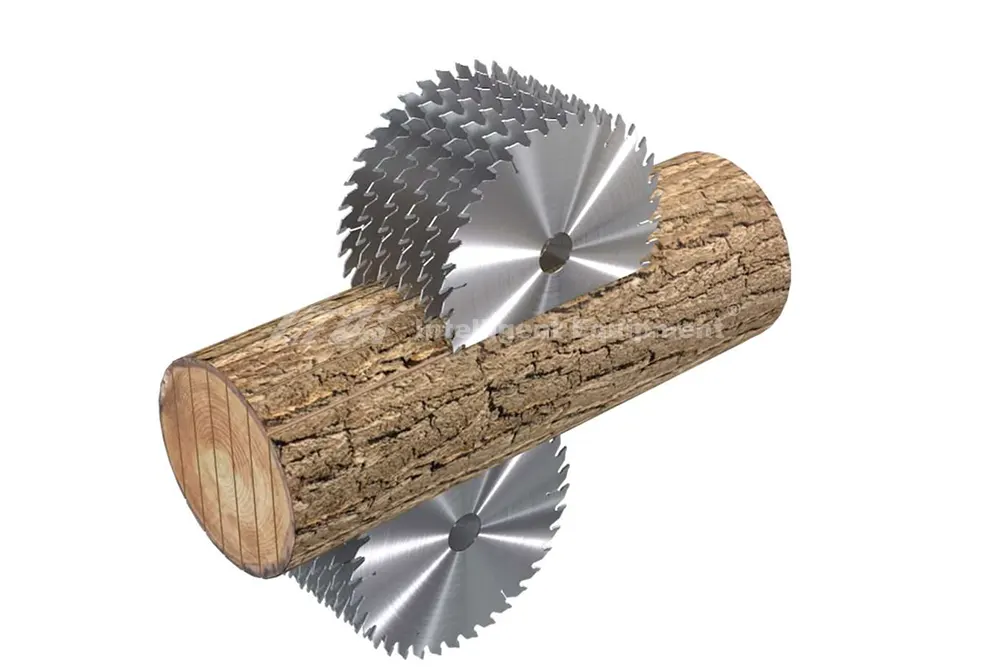

The world of Multi-Blade Saws, providing precise, efficient, and intelligent solutions for the global wood cutting market.

We make and sell machines directly to you with no middlemen. Our machines are high-quality and affordable, helping you make money.

We have 8 steps to check the quality of our machines. We have ISO and CE certification. You can use our machines for a long time.

We have a 1500 square meter warehouse. We have 80% of the machines in stock. We can send you the machines quickly.

We have dedicated after-sales engineers and teams to ensure smooth transportation and after-sales service, quick response around the clock.

SEE TO BELIEVE!

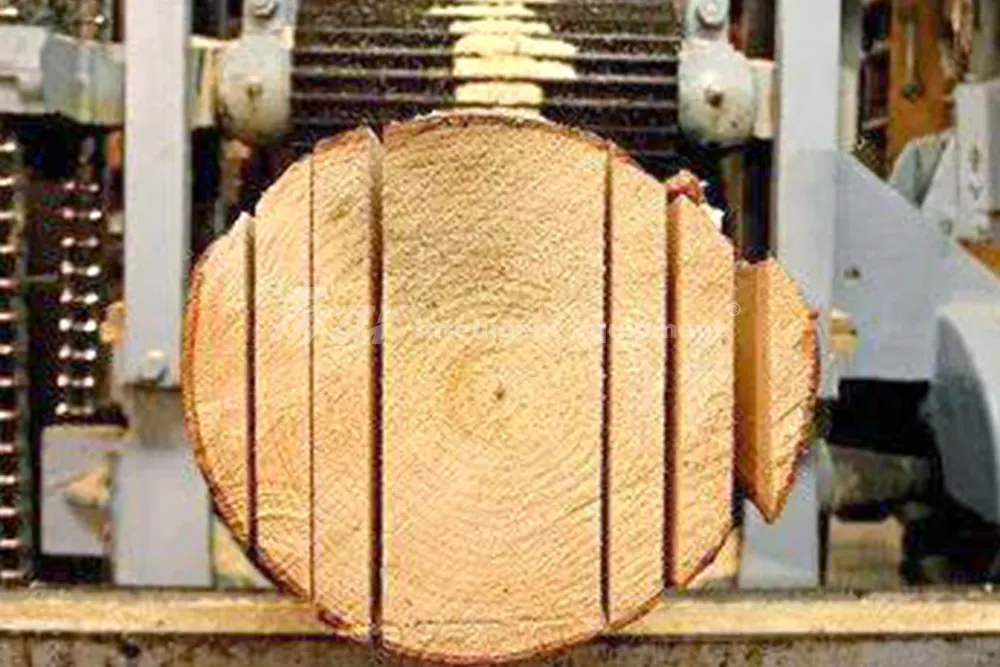

Tirox Multi-Blade Saw handles logs up to 50 cm in diameter, producing clean, stable boards without secondary cuts. In one pass, it generates 5-6 boards of varying thickness, replacing up to four traditional band saws.

With saw blades thickness of just 1.5-1.7mm, compared to the 2.5-3.0mm of standard machines, this saw reduces kerf loss by 46%. This results in a higher material yield of 76-80%, improving wood utilization by 27%. The cutting process remains stable, producing consistent, smooth, and uniform thickness boards, and even reduces the need for additional surface finishing, saving time and reducing costs.

Why choose our products?

Because we specialize in international trade and continually refine our technology by referencing renowned foreign machines, we provide products that better meet the habits of overseas users while ensuring quality.

Product Details

Every component of the Tirox Multi-Blade Saw Machine is meticulously designed for performance, durability, and ease of use.

Usage scenarios&Mechanical Models

Real case photos

| Model | ZSDPJ-20Y | ZSDPJ-25Y | ZSDPJ-30Y | ZSDPJ-35Y | ZSDPJ-40Y | ZSDPJ-50Y |

|---|---|---|---|---|---|---|

| Feed length | 50*400cm | 50*400cm | 60*400cm | 70*400cm | 70*400cm | 70*400cm |

| Feed diameter | 6--20cm | 8--25cm | 12--30cm | 12--35cm | 12--40cm | 12--50cm |

| Feeding motor power | 22/2 units | 22/30 units | 30/37 units | 37/2 units | 45/2 units | 75/2 units |

| Spindle diameter | 50mm | 50mm | 60mm | 60mm | 60mm | 70mm |

| Cooling method | Axis water spray | |||||

| Cooling water pressure | flow automatically | |||||

| Spindle speed | 3300 | 3300 | 2500 | 2300 | 2300 | 2300 |

| Feed speed | 0-10 frequency conversion | 0-11 frequency conversion | 0-12 frequency conversion | 0-13 frequency conversion | 0-14 frequency conversion | 0-15 frequency conversion |

| Blade size | 305 | 355 | 405 | 455 | 500 | 600 |

| External dimensions | 390*150*140 | 390*150*140 | 400*160*160 | 420*170*170 | 420*170*170 | 500*250*200 |

| weight | 2100kg | 2500kg | 2800kg | 3200kg | 3400kg | 3800kg |

Related Products

Our complementary products are carefully selected to enhance your machine's performance, offering a convenient, one-stop shopping experience.

Planer Wood Machine

Plank Multi Rip Saw Machine

Saw Blade Sharpener

Who I am ?

Tirox—a Chinese factory with 20 years of experience in manufacturing wood processing equipment, understanding the needs of international users.

We offer 15 series and over 50 models of wood crushing equipment. For any wood recycling needs, you can confidently choose us.What are my advantages?

Focused on foreign trade, we deeply understand the usage habits and product demands of international customers. With our own factory and no middlemen involved, we can offer you ultra-wide dual-track sawmill of guaranteed quality at more competitive prices. It perfectly aligns with your strategy of buying low and selling high.

We understand that your needs are unique, which is why we offer personalized customization services. Whether it's a hydraulic log loader, hydraulic rotation clamp, or hydraulic sawmill, our engineers can design tailored solutions for you. Additionally, we provide OEM and ODM services to ensure we fully meet your business requirements.

You can trust our extensive experience in container shipping packaging.Considering transportation conditions, we use high-strength, durable materials like fumigation-free wooden crates and iron frames to protect your products. Our long-term logistics partners provide customized transportation solutions and routes. This minimizes damage risk and ensures your timely delivery and product safety.

All exported machines come with a one-year warranty for you. We can also provide installation services. We provide lifetime online consultation and parts replacement shipping services for you. Lifetime parts will be offered to you at a very competitive price.

Here are some things you need to know!

These numbers help you understand me better.

Most Popular Questions

For your convenience, we've compiled a list of the most frequently asked questions about our wood chippers. However, if you have any other questions, please feel free to contact us.

With high-speed carbide blades and a variable-speed feed (3-10m/min), the Log Multi-Rip Saw processes up to 30 cubic meters of wood daily—4-7 times faster than traditional band saws, reducing downtime and maximizing output.

Yes, our multi-blade saws are designed with modularity in mind and can be integrated into existing timber processing lines. We can provide consultation to help you optimize your layout.

Yes, our multi-blade saws feature adjustable blade spacing and feeding speed, allowing you to easily set and change the thickness and width of the planks produced, catering to various product requirements.

To meet your specific needs, we provide OEM and ODM customization services, including color options, functionality enhancements, technical innovations, and diesel engine brands. We also offer CE and ISO certifications and support third-party inspections. These services help you differentiate your products and boost your sales.

We have a 1,500 square meter stock workshop, and shipping for in-stock machines usually takes 5-10 days. Custom machines require 20-30 days. We partner with reliable logistics companies to ensure our products are delivered quickly and safely.

The number of blades that can be installed varies by model. Our machines can accommodate up to 16 blades, allowing for flexible production of multiple planks with different dimensions from a single timber piece.

We design specialized shipping packages for each piece of equipment, using wooden crates and steel frames to ensure the product is well-protected during transport. Working with our long-term logistics partners, we provide customized shipping routes to minimize the risk of damage and ensure timely and safe delivery to your production site.

We understand the importance of after-sales support. Our machines are equipped with safety buttons and intelligent feeding features to reduce the likelihood of accidents. If your machine encounters any issues, don't worry. We assign dedicated after-sales engineers and a support team to provide 24/7 assistance, ensuring timely resolution of your needs. We also offer remote technical support and rapid parts supply to keep your machine running efficiently.

We accept payments via TT, PayPal, and various credit cards. You can opt to pay a deposit upfront, with the balance due upon successful completion and acceptance of the machine. This ensures your rights are protected throughout the payment process, giving you peace of mind.

Absolutely! We welcome you to visit our factory. We offer transportation and assist with visa procedures. During your visit, our mechanical engineers and customer managers will accompany you, showcasing our workshop and products, explaining product details, and discussing your specific requirements to meet customization needs.