Your wood chipper is not cutting like it used to. Chips are stringy, and the machine struggles. You wonder if the blades are the problem and how often you should expect to change them.

Wood chipper blades usually last between 25 to 100 operating hours before they need sharpening or replacement. This time depends on the type of wood, if there is dirt in the wood, the blade material, and how well you take care of the machine.

As a manufacturer with 22 years of experience here at TIROX, I have seen many blades. I have also heard a lot from our customers in 87 countries. How long a blade lasts is very important for how well the machine works. Let me tell you more about this.

How to tell if chipper blades are dull?

Your chipper seems to work harder, but the chips are not good. You think the blades might be dull, but you are not sure what to look for. How can you really know?

Dull chipper blades show clear signs. The machine will not work as well. Chips will be stringy or uneven. The machine will use more fuel. It will also vibrate more or sound louder. If you look closely, the blade edges will look rounded or chipped.

At TIROX, we always tell our customers that knowing when blades are dull is key to keeping their equipment working. I remember a time when a landscaping company [B2B Target Customer: Landscaping & Tree Care Companies] called us. They were worried because their chipper suddenly worked much worse. We found the blades were very dull. After we sharpened them, the machine worked like new. The clearest sign is the quality of the wood chips. Sharp blades make clean, even chips. Dull blades often tear the wood. This makes chips stringy and not uniform. You will also see the machine working harder. The engine might sound like it is struggling. You might also have to feed wood into the machine slower. This extra work uses more fuel. This costs you more money than it should. Another sign is more vibration or strange noises. Dull blades hit the wood more than they cut it. This can make the machine shake or make louder sounds. Finally, look at the blades yourself. Be careful. If the edges feel round instead of sharp, or you see nicks and chips, it is time for service. Keeping blades sharp is not just about how well the machine works. It also helps protect the whole machine from too much stress.

Signs That Your Chipper Blades Are Dull

| Sign | What It Looks Like | Why It Matters for Your Machine |

|---|---|---|

| Bad Chip Quality | Chips are long and stringy, or they are not all the same size. | Your wood is not processed well. |

| Slow Feeding | The machine pulls wood in slowly. You have to push the wood into it. | Work takes longer. You get tired faster. |

| Machine Straining | The engine sounds tired. Its speed might drop when you chip wood. | Uses more fuel. Can damage engine and clutch parts. |

| More Vibration or Noise | The machine shakes a lot. It makes loud, unusual sounds. | Parts wear out faster. |

| Visible Blade Damage | The blade edges are rounded. They have nicks or chips. | Blade cannot cut well. |

| Higher Power Use | The machine needs more fuel or electricity to do the same amount of work. | Costs more money to run. Not good for the environment. |

Knowing these signs fast helps make sure your TIROX equipment keeps giving you the “Made in China + International Quality” you bought it for.

How long does a wood blade last?

You are trying to plan your work schedule and how much money you need for new parts. A big question is, how many hours can you really expect from a set of wood chipper blades before you need to do something with them?

A wood chipper blade will usually last between 25 to 100 operating hours. But how long it lasts greatly changes based on the type of wood, if the wood is clean, the blade’s material, and how you use the machine.

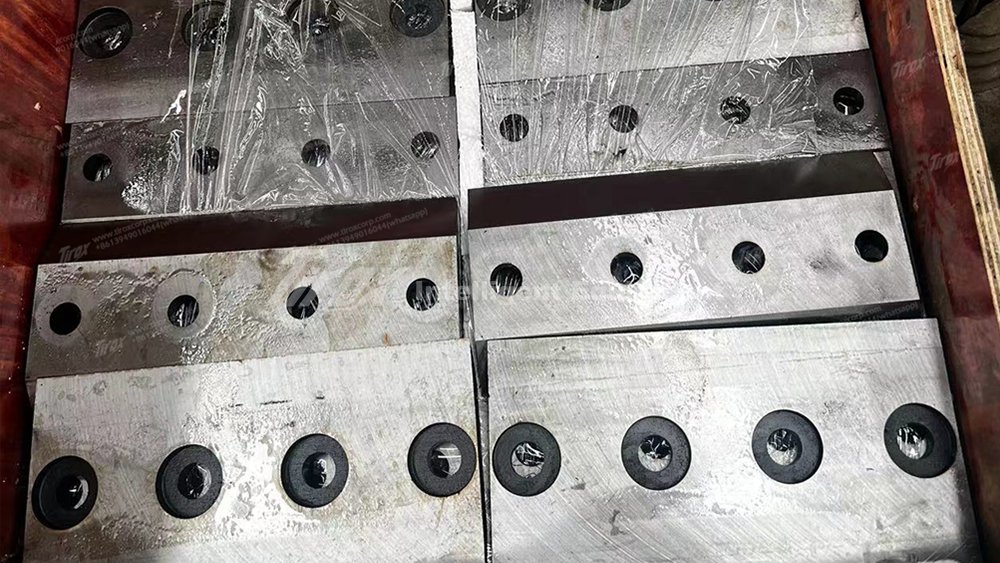

In my time at TIROX, I have seen this a lot. Blades used by forestry companies [B2B Target Customers: Forestry & Logging Companies] cutting clean, soft wood last much longer. Blades used by waste management centers [B2B Target Customers: Waste Management & Recycling Centers] processing mixed city waste often have a shorter life. That mixed waste might have dirt or small pieces of trash. The type of wood is a big factor. Hard woods like oak or maple will wear blades down faster than soft woods like pine. Dirty wood, or wood with soil, sand, or small rocks, wears blades out very fast. Even if you hit a small piece of metal by accident, it can damage a blade right away. The quality of the blade material is also very important. We use strong, hardened steel for our blades. This helps them stay sharp longer and stops them from chipping. Taking good care of the machine, like making sure the anvil (the fixed blade) is set right, also helps. If the anvil is not set correctly, it can make blades wear out or break too soon. We also remind our customers that most industrial chipper blades can be sharpened many times. This means they last longer overall and give you more value. This is part of how we make our equipment cost-effective.

Things That Change How Long Your Blade Lasts

| Factor | How It Affects Blade Life | What TIROX Does |

|---|---|---|

| Wood Type and Hardness | Hard woods (like oak) wear blades faster than soft woods (like pine). | Our machines can handle many wood types, but blade life will be different. |

| Wood Condition | Clean wood means longer blade life. Dirt, sand, or trash make it much shorter. | We tell customers to clean wood before chipping. This helps blades last longer. |

| Trash in Wood | Metal, stones, or other items can chip or break blades instantly. | Our feeding systems are strong. But trash is very bad for blades. Sometimes smart feeding systems can help a little. |

| Blade Material Quality | High-quality, hardened steel blades stay sharp longer and resist damage. | TIROX uses top-grade materials for our blades. This is a key part of our “International Quality” promise. |

| How You Operate Machine | Feeding too much wood, or forcing it, can harm blades. Feeding at the right speed is key. | Our smart feeding systems help with this. But the person using the machine also needs to be careful. |

| Anvil Setting | The right gap between the blade and the anvil ensures good cutting and stops extra wear. | We give clear instructions on how to set the anvil. Our 24/7 after-sales support can also help. |

Knowing these things helps our customers get the most out of their TIROX chipper blades.

How long does a wood chipper last?

Buying a wood chipper is a big choice for any business. You are not just buying a tool; you are investing in getting work done. So, a very important question is: how many years of good service can you expect from the machine itself?

A commercial wood chipper that is taken care of well can last for many years. Often, it lasts 10 to 20 years or even more. How long it lasts depends on how it is built, how often and hard it is used, how you maintain it, and where it works.

Here at TIROX, with our 22 years in this industry and products in 87 countries, we build our machines to last. I have heard from customers who have used our equipment for over ten years, and it still works great. Our “Made in China + International Quality” idea means we use strong materials and proven engineering. Regular maintenance is the most important thing. This means checking it often, adding grease, changing blades and belts on time, and taking care of the engine. How much the machine is used also matters. A chipper used every day by a big biomass energy company [B2B Target Customers: Biomass Energy Companies] will wear out faster than one used a few times a week by a smaller landscaping service. The place where it works also makes a difference. Machines used in dirty, dusty, or very wet places might need more care. Our new tracked equipment, like the Tracked Horizontal Grinder, means these machines are made for tough places. Their long life shows their strong design. A wood chipper is a long-term asset. With good care and help from a good manufacturer like TIROX, which offers 24/7 after-sales support, customers can expect many years of good work. This is why we like factory visits. Seeing how we build things helps build trust in our quality.

Things That Determine How Long Your Wood Chipper Will Last

| Factor | How It Helps the Machine Last Longer | How TIROX Helps |

|---|---|---|

| Build Quality and Parts | Strong steel, good welding, durable parts (bearings, hydraulics, engine). | 22 years of making machines. We focus on “International Quality.” We use strong materials. |

| Regular Maintenance | Oiling parts, taking care of blades, changing filters, servicing engine, checking machine. | We give clear maintenance plans. We have 24/7 after-sales support. Over half of our engineers speak English well for easy talks. |

| How Much You Use It | How many hours per day/week it runs. What kind of wood it chips regularly. | Our machines are made for different jobs. Some are for using now and then. Some are for constant use in big industrial places. |

| Where It Operates | If it is exposed to rain, dust, or rough ground (for mobile machines). | We build strong machines like Tracked Horizontal Grinders. They can work in difficult places. |

| Operator Skill | Using it correctly. Not putting too much wood in. Noticing problems fast. | Our machines are easy to use. We give clear guides on how to run them. We can also give training help. |

| Parts Availability | Easy to get real replacement parts for fixing and upkeep. | We ship to 87 countries. We know it is important to have parts ready. We give support for this. |

A TIROX wood chipper is built to be a strong partner for your wood processing needs for many years.

Conclusion

With good care, chipper blades last 25-100 hours. The chipper itself, built with quality like ours at TIROX, can work reliably for many years.