You’ve invested in a wood chipper, a powerful tool that transforms woody debris into usable material. But to truly unlock its potential and ensure it serves you reliably for years, you need more than just brute force.

For optimal wood chipper performance and longevity, prioritize consistent maintenance, use only appropriate materials, understand its specific type, and always adhere to strict safety protocols for both operation and assembly to prevent damage and ensure operator well-being.

In my 22 years of experience at TIROX, manufacturing and exporting wood chippers worldwide, I’ve seen countless machines deliver exceptional results when properly cared for. Conversely, even the most robust equipment can fail prematurely without the right approach to its service, maintenance, and understanding its intrinsic design. It comes back to knowing your machine and respecting its capabilities and limitations.

Wood Chipper Service, Repair, Parts, & Maintenance: How Do I Keep My Machine Running Smoothly?

You’ve got a workhorse in your wood chipper, constantly processing tough materials. But like any heavy equipment, it needs regular care to prevent breakdowns and keep it performing at its best.

Maintaining your wood chipper involves daily checks of safety features and blades, regular lubrication, proper belt tensioning, diligent hydraulic system care, timely engine servicing, and continuous cleaning to ensure optimal operation, minimize wear, and quickly address any issues to prolong its lifespan.

During my time helping customers globally, one of the most common issues I address is directly related to maintenance. Many problems can be prevented or quickly resolved with a proper maintenance routine. For instance, I recall a customer in Europe who called about decreasing output and an unusual vibration. After leading them through a diagnostic, we found their blades were extremely dull. A quick blade sharpening solved their problem and significantly improved performance. We build our machines tough, from high-strength steel, but even the best materials need care.

Comprehensive Maintenance Schedule

Proper maintenance is the backbone of a reliable wood chipper. Before each use, you should visually inspect the blades for any damage like chips or cracks. Every 10 hours, check the cutting tools. Ensuring blades are sharp and correctly secured is critical for efficiency and safety. Regularly lubricate all moving parts, including bearings, rollers, and drive components, following the manufacturer’s recommended schedule. Check and adjust belt tension periodically to ensure efficient power transmission. For models with hydraulic systems, inspect hoses, fittings, and fluid levels regularly, and promptly replace any worn or damaged components. Lastly, performing engine maintenance, such as oil changes and filter replacements, according to the engine manufacturer’s plan, is vital.

Blade Care is Key

The sharp blades are the heart of your chipper. Their wear rate depends on the type of wood, its cleanliness, and if any foreign objects are present. Hardwoods will dull blades faster than softwoods. Impurities like sand in the material can significantly reduce blade life, sometimes requiring sharpening every 2-3 hours. You can tell blades are getting dull if the machine’s energy consumption increases by over 15%, the output drops significantly (30-50%), or you notice unusual vibrations or noise. When sharpening, grind no more than 0.1mm at a time, and ensure an angle tolerance of ±0.5° . Keeping blades sharp protects your engine from unnecessary stress and maintains output quality. Regularly check out the TIROX blog for valuable insights on machine care: https://tiroxcorp.com/blog/

Parts and Repair Accessibility

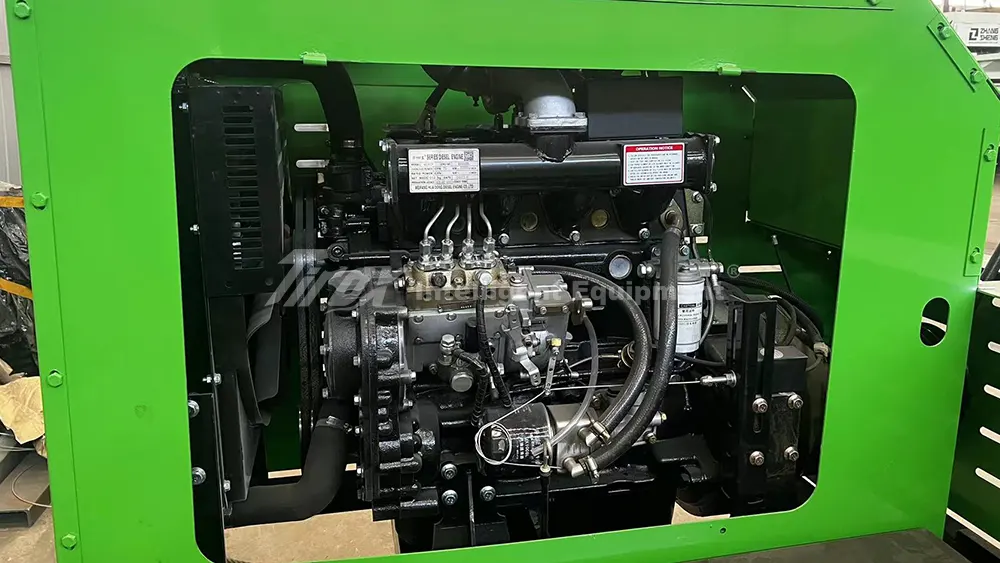

When it comes to parts, we understand the importance of availability. That’s why we offer high-quality Chinese diesel engines or globally recognized brands like Cummins, Perkins, Huadong, and Weichai for our chippers. This makes sourcing replacement parts and performing repairs much easier for customers. Our machines also feature intelligent control panels that display critical working conditions like oil levels, water temperature, and running time. This early detection system helps in identifying issues before they escalate, minimizing maintenance downtime. In case of a jam, our user-friendly controls allow for quick stopping or reversing of the feed to protect blades and the diesel engine.

Building a chipper: What Goes Into Designing a Reliable Machine?

When you consider a wood chipper, you might only see the exterior. But what unseen engineering choices and manufacturing processes go into building a machine that can withstand the rigors of heavy-duty work?

Building a reliable wood chipper involves integrating robust construction with intelligent design features such as hydraulic forced feeding, smart control systems, and durable materials, all aimed at enhancing efficiency, safety, and operator usability in diverse raw material conditions.

From my vantage point at TIROX, the process of designing and building a wood chipper is a painstaking one, honed over two decades of experience. It starts with understanding what customers need in the field. Our goal is always to create a machine that is not just powerful but also intelligently designed to handle various types of raw materials. We conduct an 8-step rigorous quality inspection before our machines even leave the factory.

Key Design and Engineering Principles

Our wood chippers incorporate several key design features to optimize performance and safety. The hydraulic forced feeding system is crucial; it adapts to varying material diameters, ensuring optimal performance and higher output. This system ensures even challenging wood materials are efficiently pulled into the cutting mechanism. An intelligent feed system monitors the processing load in real-time, automatically adjusting feed speed or stopping to prevent blockages. This smart feature ensures smooth operation and protects the machine from potential damage.

Material Quality and Construction

Durability is a cornerstone of our manufacturing philosophy. We use high-strength steel and advanced manufacturing processes in the construction of our wood chippers. This choice of materials provides excellent wear resistance and impact resistance, ensuring the machine can handle tough conditions and extend its operational life. Every component, from the main chassis to essential parts like engines and conveyers, is selected for resilience. For example, our common ZSYL-1063 models can come with different engine options from trusted brands that ensure reliable power sources.

Enhancing User Experience and Safety

User-friendliness is integrated into the design. Our intuitive control levers allow for effortless management of functions like forward, reverse, and stop. The smart control panel keeps operators informed of key working conditions, such as oil levels and water temperature, helping to detect issues early and minimize maintenance. We also offer customizable options, such as road-worthy configurations or specific track types (like rubber or steel). This allows clients to tailor the machine to their specific operational needs, whether for mobile operations or stationary setups, further ensuring safety and efficiency. For more details on our specific machine models and their features, you can visit our website: https://tiroxcorp.com/products/.

BRIEF INTRODUCTION OF WOOD CHIPPERS: What Are These Machines and How Are They Used?

You see wood chippers at work in various settings, from landscaping sites to large forestry operations. But what exactly are they, and how do these powerful machines transform bulky woody waste into useful resources?

Wood chippers are specialized machines designed to cut and process woody organic plant matter, primarily branches and small tree trunks, into smaller, more manageable pieces called wood chips, which are then used for purposes like mulching, composting, or biomass energy production.

In my two decades in this industry, I have seen wood chippers evolve into indispensable tools for efficient wood waste management and resource recovery. They are not merely disposal units but key components in a sustainable cycle. Understanding their basic function, types, and how to use them effectively is fundamental. You can find general information about wood chippers on various platforms, such as the Wikipedia page for Wood Chopper.

Types and Functions of Wood Chippers

Wood chippers primarily handle woody organic plant matter, including branches, limbs, and tree trunks within their specified diameter capacity. Beyond the general term “wood chipper,” there are several specialized types:

- Garden wood chipper (portable wood chipper): Common for smaller branches and residential use. Models like our 1063 are comparable to units like the Vermeer BC1000XL.

- Horizontal grinder: Designed for large-scale processing of various materials, including construction debris, green waste, and even railway sleepers. It can handle large dimensions and hard materials, often featuring a hammer rotor for material containing iron or stones.

- Disc chipper: Produces uniform wood chips, often 3 cm wide and less than 1 cm thick, ideal for paper mills or biomass fuel.

- Drum chipper: Similar to horizontal grinders, these are robust, fixed installations for processing larger volumes.

These machines often come equipped with hydraulic feeding systems that pull material into the cutting chamber, where rotating blades or hammers reduce it to chips.

Recommendations for Use

To maximize the efficiency and safety of a wood chipper, always follow key operational guidelines. Wear appropriate Personal Protective Equipment (PPE), including safety goggles, hearing protection, gloves, and steel-toed boots. Stand to the side of the feed chute to avoid potential debris ejection. Use a pushing tool, not your hands, to feed branches into the chipper. Never reach into the machine while it is running, and avoid loose clothing or jewelry that could get caugh. In case of jams, always turn off the chipper and wait for all moving parts to stop completely before attempting to clear the obstruction. Regularly cleaning the chipper of debris also prevents overheating and other issues. For detailed safety practices, refer to our blog about safe operation of wood chippers.

Understanding Raw Material Adaptation

Different waste materials require different chipper specifications. Hardwoods need more robust chippers than softwoods. If your raw materials are large in diameter, you need a chipper with a larger feed size. The final use of the wood chips (e.g., smaller uniform chips for biomass fuel, higher quality for papermaking, or larger for garden mulch) also guides the choice of equipment. Our machines are designed to adapt to various raw materials and can produce chips in different sizes depending on your needs. For instance, our drum chippers can produce chips from 10-20mm to 30-50mm, and our wood crushers can produce sawdust from 3mm to 25mm.

Conclusion

Proper wood chipper advice emphasizes that consistent maintenance, an understanding of the machine’s design and features, and adherence to safety protocols are crucial for its efficient operation, longevity, and overall user safety.